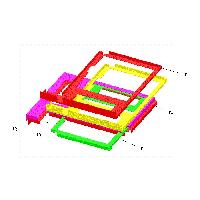

The stacking planner generates plans for polyhedral sheet metal parts. Sheet metal parts used in electronic/consumer product domain have irregular geometry and are difficult to stack. While a lot of work has been done on automated planning for other stages of sheet metal manufacturing, stacking plans are still generated by shop floor personnel. The focus of this work is to generate the stacking plan for a given set of parts and part buffer on which the stack is built.

The stacking plan is described by a set of transformations describing the position and orientation of each part in the stack with respect to a world coordinate system. This plan would then have to be converted into a set of instructions for the part handling mechanism. The planning is comprised of two parts. First, candidate configurations are generated for parts constituting the stack. Next, the feasibility of the part configuration is checked by ensuring no part-part interference and evaluating stability of the stack using screw theory.